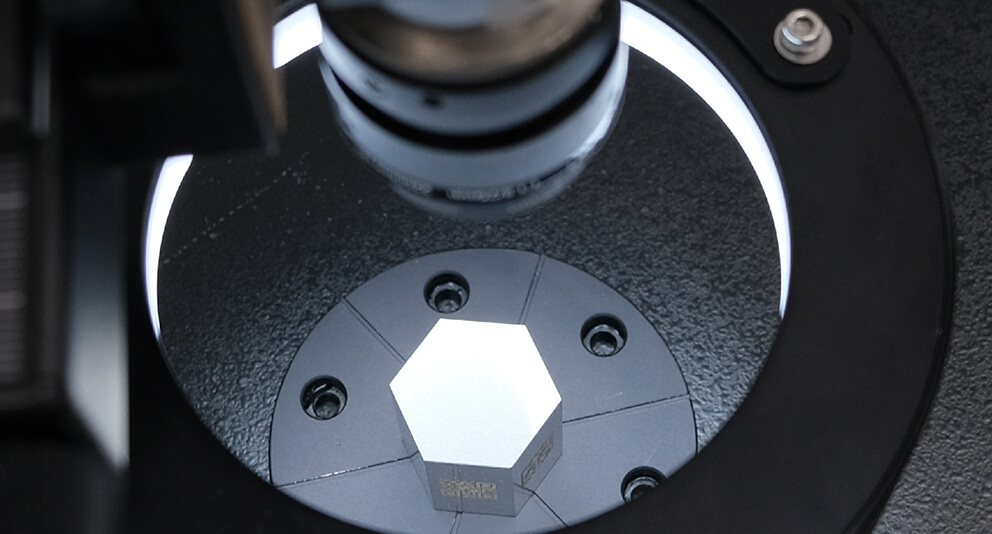

1. Utilizing the latest machine vision technology2. Supports all kinds of workpiece shapes and inspection items3. Total solutions are possible, including not only visual inspection units and software, but also auto handlers, etc.What the AVI test can do for you?

Various types of image processing filters are available for inspection, pattern matching for high-speed image processing, and sub-pixel processing for high-precision measuring of dimensions. The camera calibration function improves measurement accuracy.

The analysis of geometrical features enables the classification of linear and subtle defects, color determination, code reading, and even text recognition using OCR.

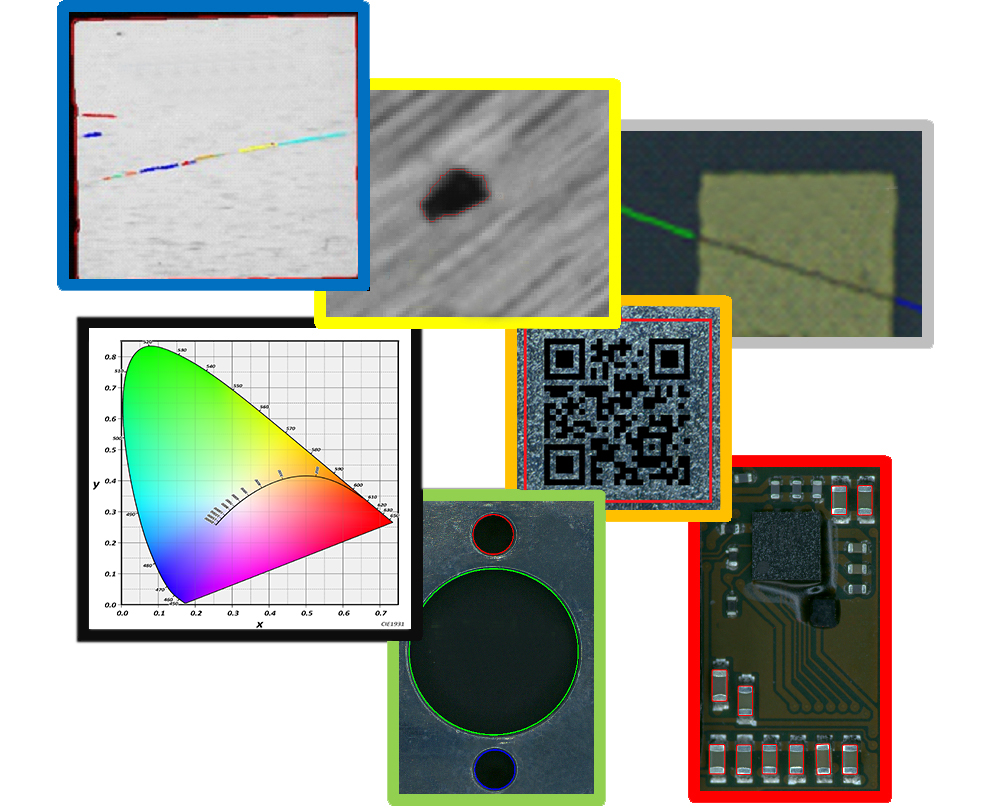

Case Studies

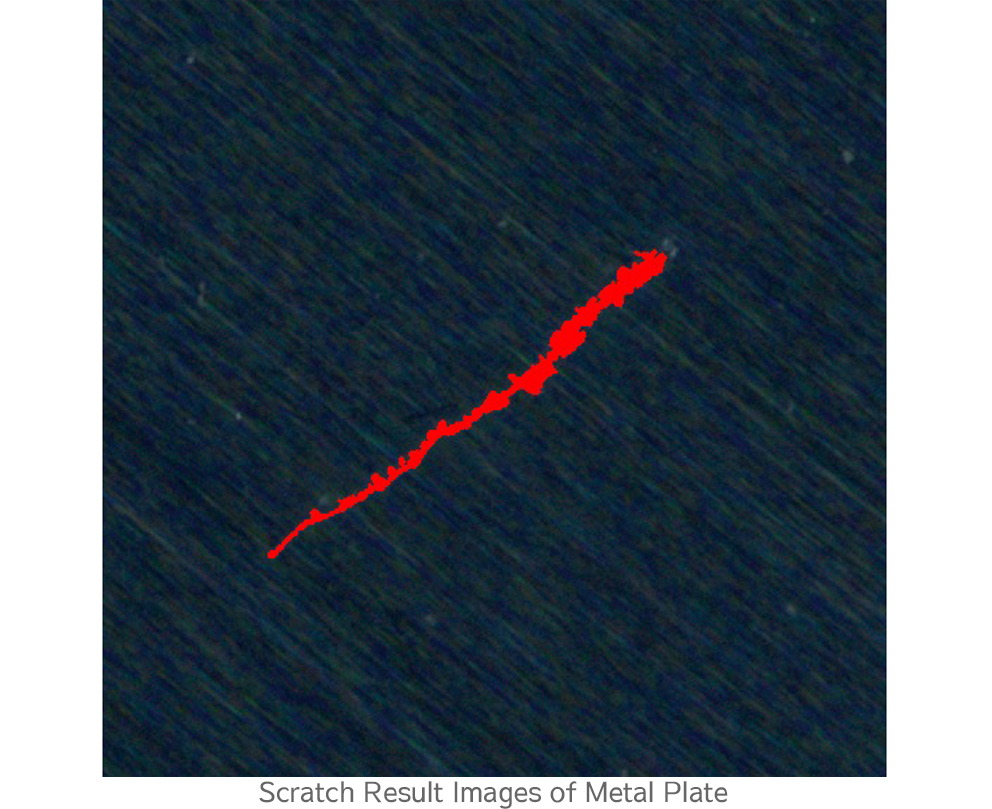

【Flaw inspection of metal plates】

The outer shape of the metal plate is detected by edge extraction to narrow down the inspection area for flaw inspection. For flaw inspection, sub-pixel processing can be used to detect flaws with an accuracy of 1/10 to 1/50 of the pixel size.

We have a track record of measuring the size of scratches with a resolution of 0.36um by using a telecentric lens and analyzing the shape feature quantity. We also have experience in the inspection of line scratches and dents, and will propose the selection of camera and lens according to the target size. We can inspect all kinds of scratches on metal, resin, and other materials.

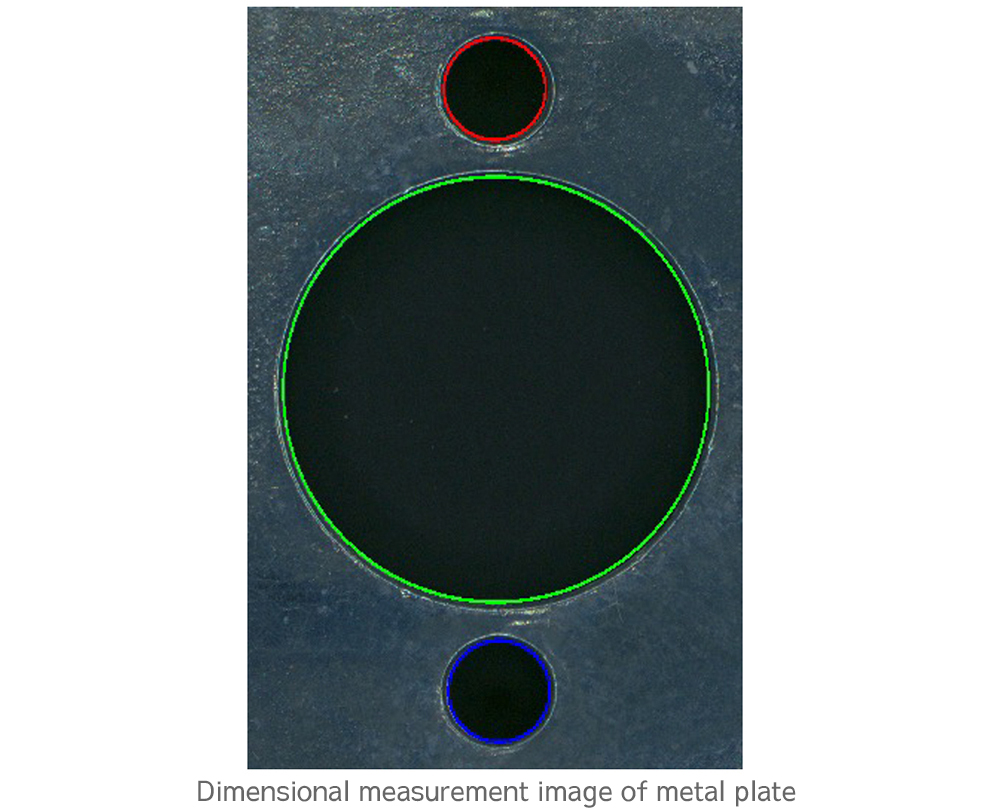

【Measurement and inspection of the dimensions of metal plates】

The equipment detects holes on a metal plate by means of an edge extraction process. Using the characteristics of the arc component, it is possible to measure the length and width by circular approximation. In addition, the lens distortion is corrected using a calibration chart for highly accurate measurement.

After calibration, the measurement error is within 0.41um. The equipment can also measure the diameter of a circle, arc, roundness, and other unique shapes.

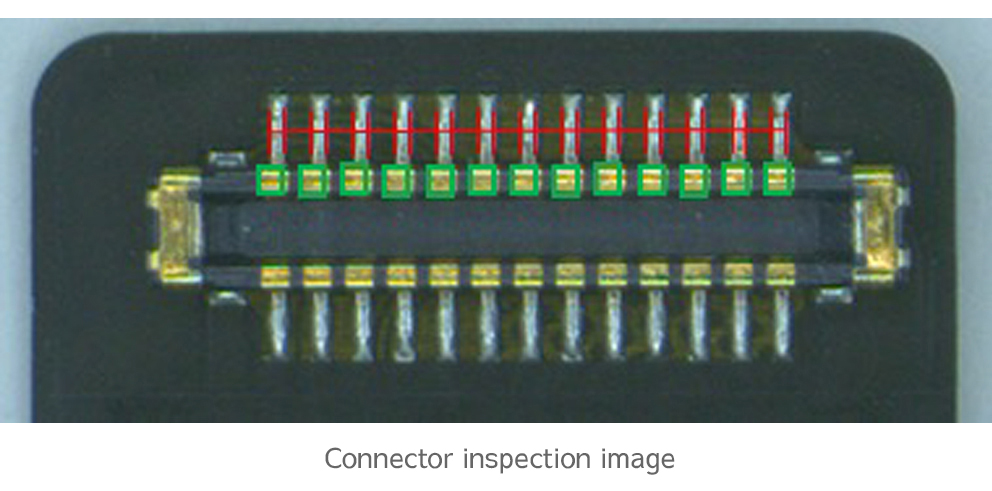

【Connector connection inspection】

Performs connector shape-based pattern matching to accurately detect patterns and confirm the soldering condition of the connector pins to be measured. Also, by inspecting the connector connection for foreign matter, we can reduce defects at the time of contact.

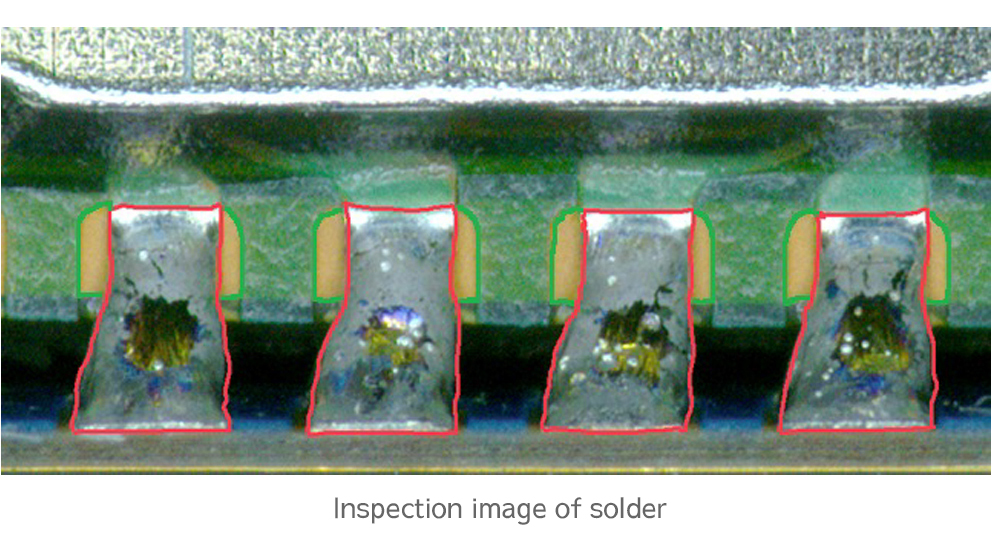

【Soldering inspection】

In inspecting after soldering, it is possible to determine the state of soldering by extracting subtle changes in the solder and acquiring boundary line edge information with sub-pixel accuracy to determine the land surface area of the soldering area and the wetted surface area of the solder. This can be used to inspect the soldering of components onto PCBs, wire soldering of harnesses, etc., and other types of soldering.

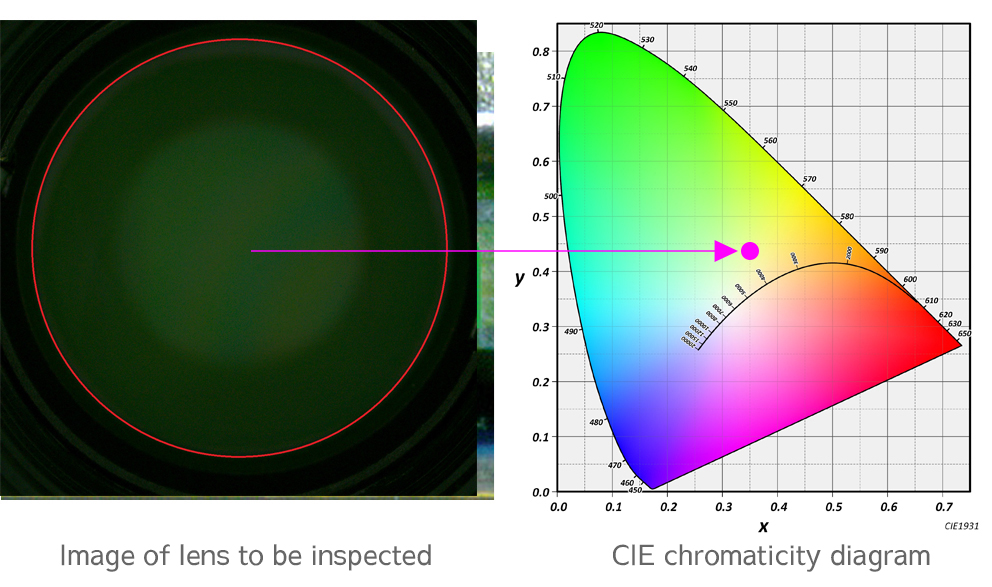

【Lens surface AR coating inspection】

The inspection is performed to check for unevenness, foreign matter, peeling, etc. of the AR coating on the surface of the lens. The AR coatings are inspected by detecting the target part of the lens at the edge, and then making a subtle color judgment on the entire lens. The protective coating on the surface of the lens barrel can also be inspected by judging the color tone. The color tone is calculated based on the degree of coloration, so it is possible to determine the color in great detail.

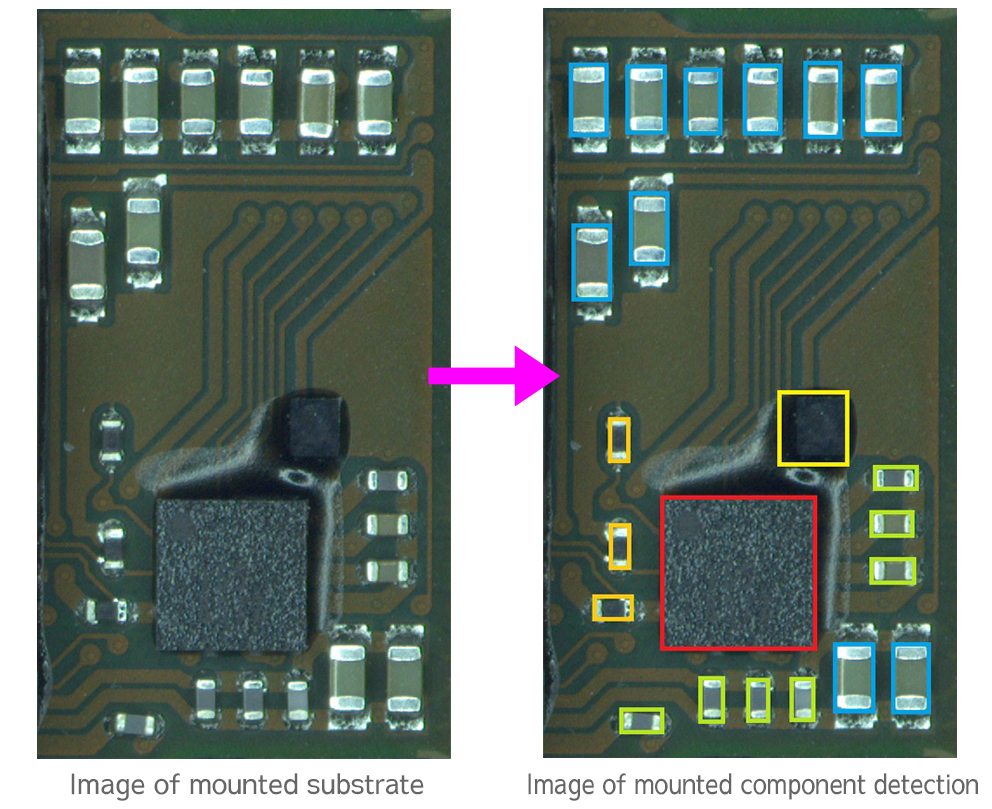

【Component mounting inspection】

In the inspection of component mounting on boards, shape-based pattern matching is performed to identify components by distinguishing objects, and to determine that components are mounted in the correct position. It is also possible to perform inspections for component mounting misalignment and solder amount at the same time. Component mounting inspection can be performed for different size components at the same time.

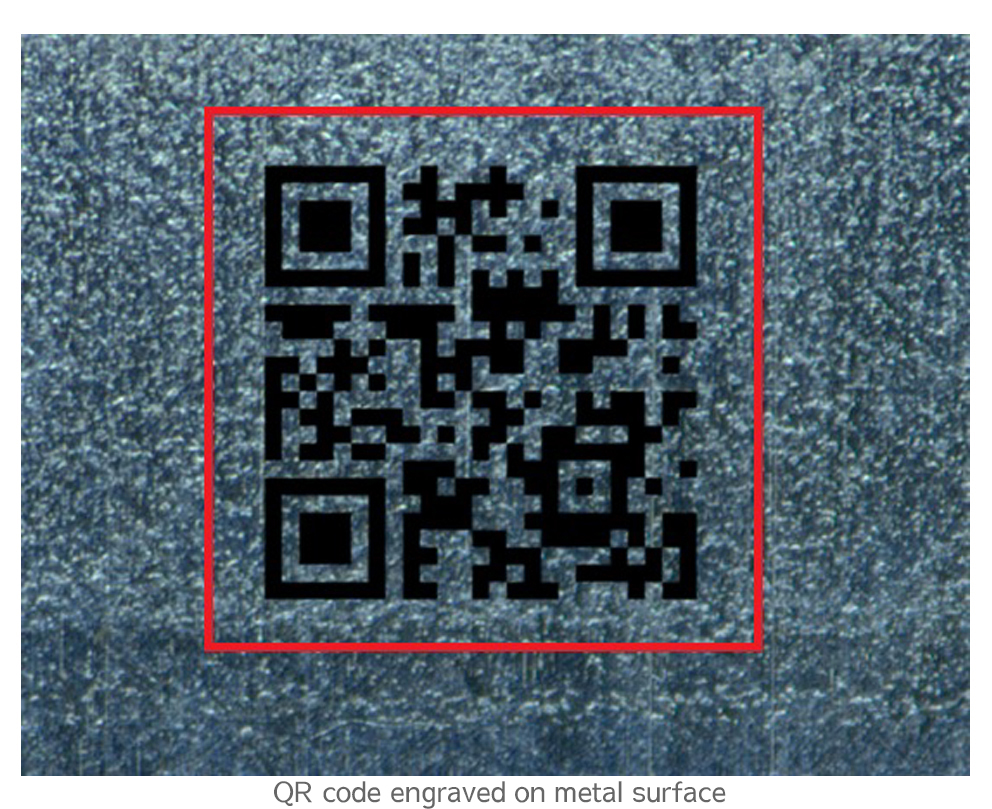

【QR code reading】

QR Codes imprinted on metal and plastic surfaces can be read. The system detects the data code area in the image data and performs decoding. OCR is also possible and can read the text and figures engraved on the part. ECC (DataMatrix) and PDF417 (2D code) are also available.

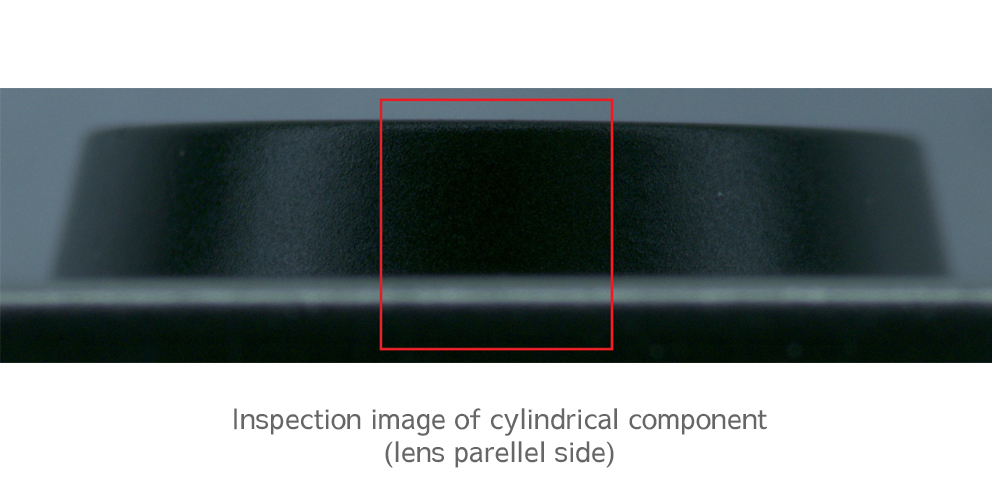

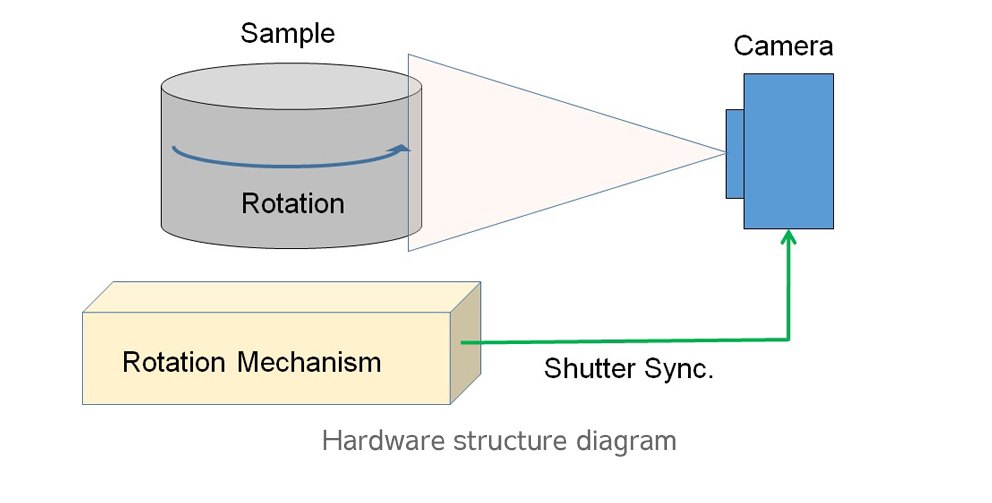

【Inspection of cylindrical parts】

We can also provide the hardware control which is necessary to automate visual inspections.

The following is an example of a cylinder-shaped object being inspected by performing motor control to rotate the object while acquiring images and inspecting all surfaces in 360°. Hardware control is also available to inspect any shape. We also offer hardware configurations to suit your needs, such as laser measurement.