1. Highest processing ability, UPH = 1,000;2. Widely applicable (Smart Phone, Automotive, Industrial Camera., etc)3. Capable to large size sensors, sensor size > 1 inch4. Solution to reduce total yield loss, improve utilization ratioWhat is Active Alignment (AA) ?

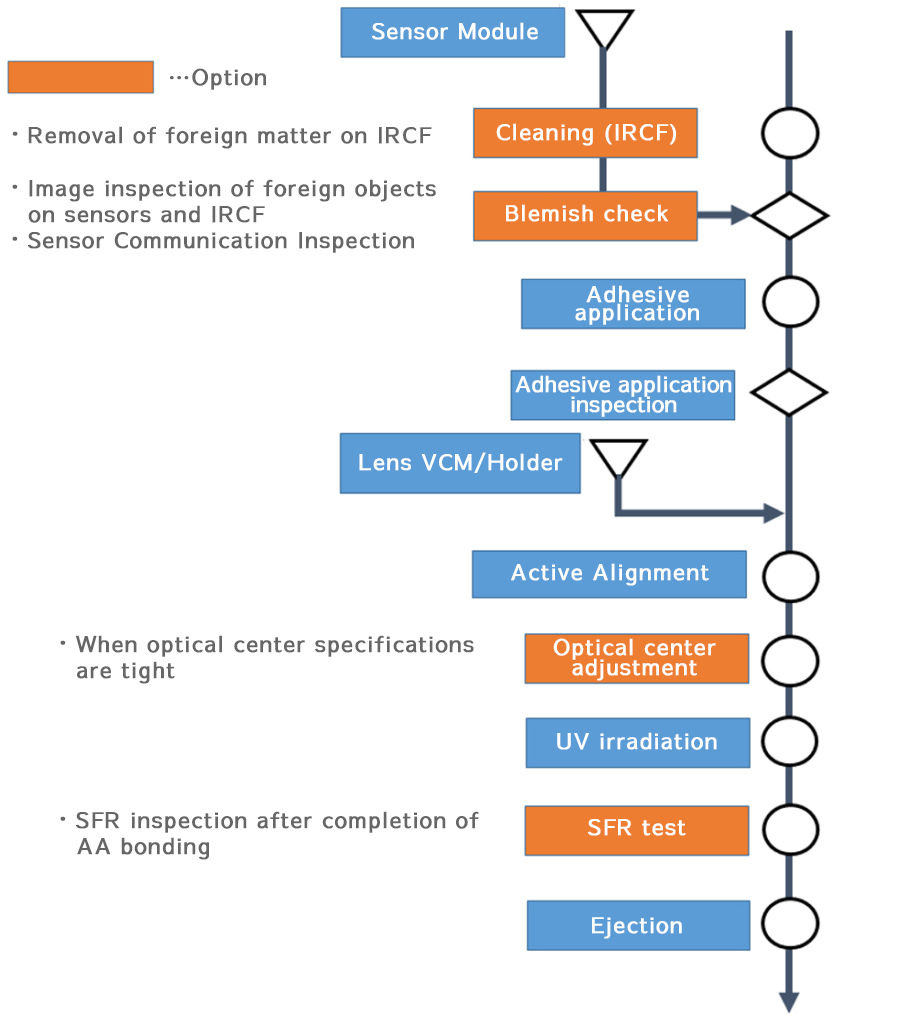

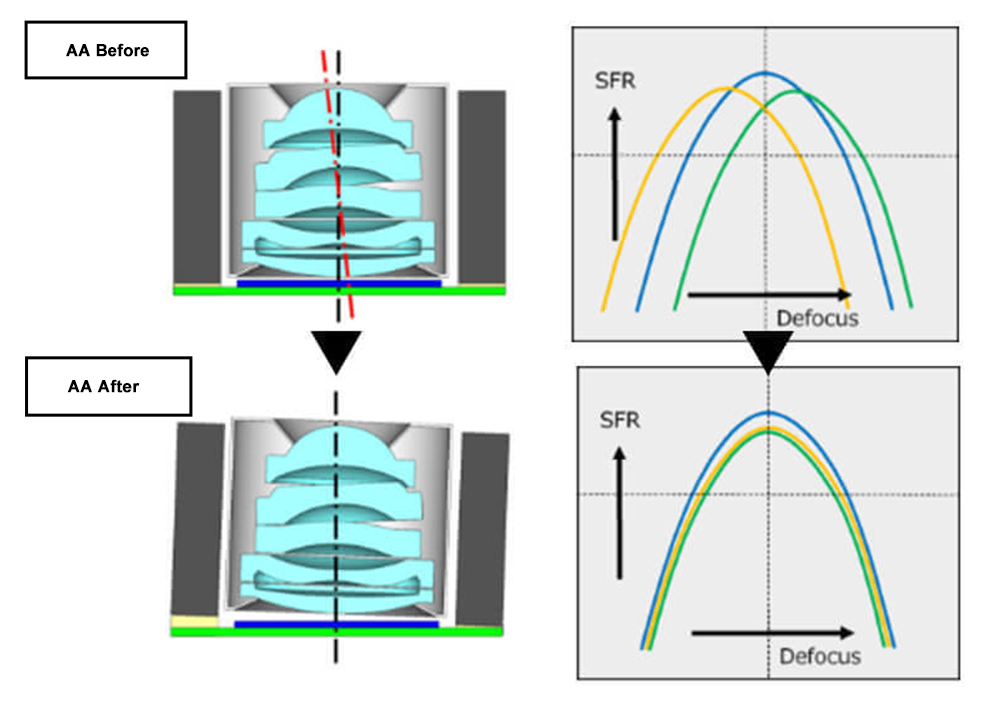

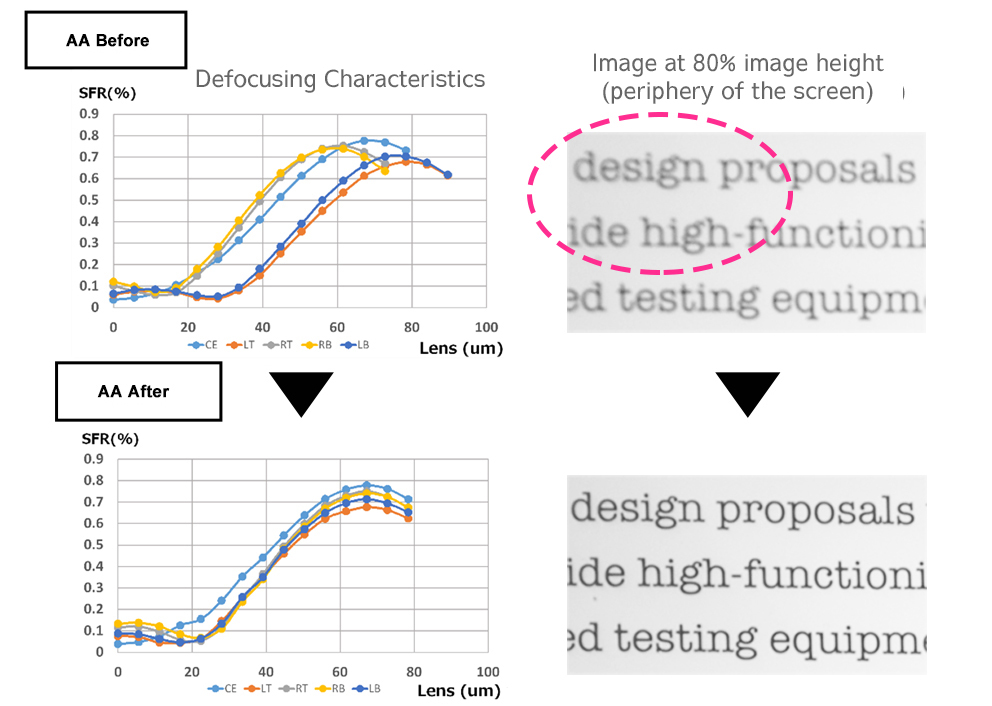

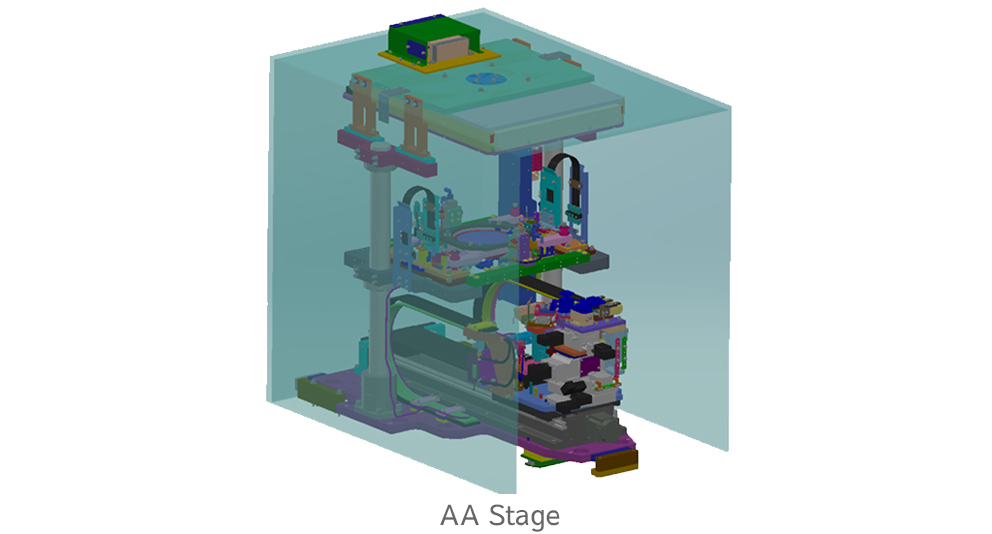

This device adjusts the optical axis of the sensor and lens unit using a 6-axis alignment unit during the assembly of the camera module. Afterward, it fixes them in place with UV + thermosetting adhesive while maintaining the completed adjustments. This system prevents one-sided blurring that occurs around the screen, improves image quality, and increases yield.

Effects of Active Alignment

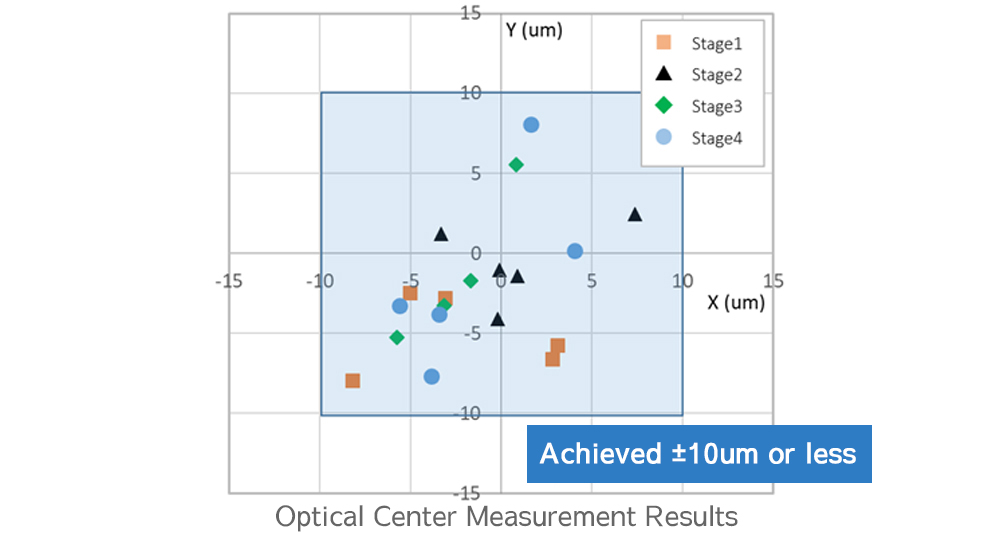

AA Adjustment Process and Accuracy

1. Apply UV+thermosetting resin to sensor module

2. Supply lens + VCM or holder

3. Supply ① and ② to AA stage

4. Obtain defocus characteristics

5. Calculate correction value

6. Adjust 6 axes (X, Y, Z, θ, Xθ, Yθ) corresponding to correction values

7. UV irradiation in corrected state

8. Discharge module after AA

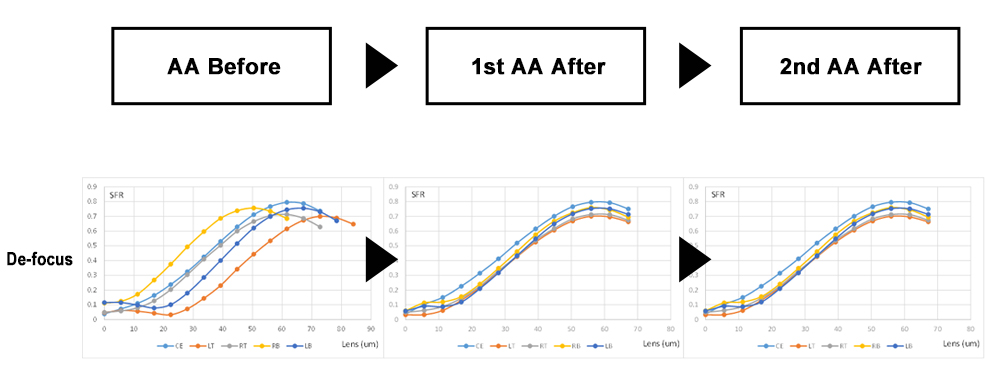

One AA adjustment aligns the center and peripheral peaks, and completes the AA.

The optical center value achieves less than ±10um misalignment between the sensor center and the lens luminance center, and if even higher precision is required, X,Y adjustment is possible during AA.

AA equipment proposal according to application

| use | AA Stage | UPH * | FOV (angle of view) | handler |

| smart phone | ~4 | ~1000 | ~150° | fully automatic |

| In-vehicle | 1~ | 150~200 | ~210° | fully automatic semi-automatic |

| Industrial | 1~ | 150~200 | ~150° | fully automatic semi-automatic |

Yield improvement options

Pre-tests of modules to be fed into AA can be installed in the equipment for screening upon request.